Phantom has a wide and extensive range of burrs. In this range, you will find coated versions, models with a 3 mm, 6 mm and 8 mm shank and new tooth forms. These new tooth forms are designed for use with steel and stainless steel.

All the models from the Phantom range of solid carbide burrs are available in stock for you in a range of diameters and lengths. At Phantom, you will always be able to find the burr you are looking for!

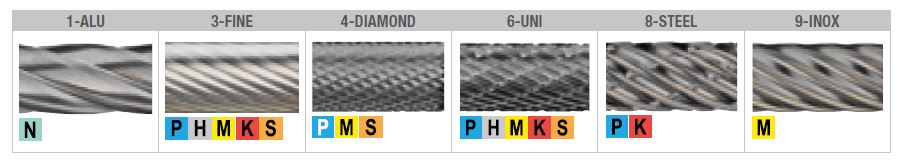

We distinguish between the following tooth forms:

1-ALU

Very suitable for machining aluminium, light metals, non-ferrous materials and plastics.

3-FINE

For a smooth surface when machining steel < 60 HRc, stainless steel, cast iron and nickel and titanium alloys.

4-DIAMOND

High material removal rate and short chips. Ideal for machining stainless steel and nickel and titanium alloys. Fast machining and perfect chip breaking.

6-UNI

Most universal toothing profile with high material removal rate when machining steel < 60 HRc, stainless steel, cast iron and nickel and titanium alloys.

8-STEEL

Specially designed for cutting steel and cast steel. Aggressive, very suitable for machining and excellent continuous guidance, guaranteeing safe and accurate working.

• Saves time due to excellent machining ability when used on steel and cast steel compared to traditional forms of toothing profiles.

• Lower thermal load on the workpiece and tool.

• Comfortable and ergonomic working due to quieter operation with reduced vibrations and less noise.

• Aggressive tooth geometry, large chips and very good chip removal.

9-INOX

Specially for cutting high-grade steel (stainless steel).

The INOX toothing is characterised by an extremely high machining capacity when used on all austenitic, rust-resistant and acid-resistant steels.

• High machining capacity.

• Long tool life due to the special geometry of the teeth.

• High surface quality thanks to optimum chip formation.

• Prevents heat discolouration in the material due to the low generation of heat.

Other new additions include Phantom router cutters, with staggered teeth specifically designed for cutting fibre-reinforced plastics (GRP/CRP) on both conventional and CNC machines. Besides these developments, Phantom is also able to supply Phantom pneumatic grinders enabling us to offer you a complete solution.